Industrial Waste-to-Energy

A Step towards Reduced Carbon Footprint

Incinerating industrial wastes to energy is becoming an increasingly attractive option for businesses looking to reduce their environmental footprint and become more sustainable. By utilizing this form of thermal treatment, industrial waste can be safely and effectively converted into energy, allowing businesses to reduce their dependence on finite resources and eliminate the burden of disposal. With its potential for cost savings, reduced environmental impact, and improved safety, incinerating industrial waste to energy is a viable option for businesses and organizations.

Industrial waste to energy (WtE) is the process of generating energy from industrial waste streams. This form of energy production has been around for many years, but as technology continues to evolve, it is becoming an increasingly viable option for businesses, municipalities, and other organizations that are looking to reduce their carbon footprints. Industrial WtE can be used to generate electricity, heat, and transportation fuels, among other forms of energy.

The WtE process works by incinerating industrial waste, such as plastics, paper, wood, and other materials. The incineration process produces heat, which is then converted into electricity through either steam or gas turbine generators. The resulting electricity is sent to the local power grid or used to power on-site or nearby power off-taker operations. In addition to producing electricity, WtE can also be used to generate heat for industrial processes, such as drying and heating. This process can be very efficient, as the heat produced is often used to pre-heat incoming air, reducing the amount of energy required to heat the space. The WtE process also has the potential to generate transportation fuels, such as biodiesel, ethanol, and other biofuels. These fuels can be used to power vehicles and other equipment, reducing the need for fossil fuels.

The benefits of WtE are numerous. It can reduce the amount of waste that is sent to landfills, as well as reduce the amount of carbon dioxide and other pollutants that are released into the atmosphere. Additionally, it can reduce the need for traditional energy sources, such as coal, oil, and natural gas, which can help reduce the cost of energy production.

Despite the many benefits of WtE, there are also some drawbacks. One of the main concerns is the release of pollutants during the incineration process, which can be harmful to both human health and the environment. Thankfully, the modern flue gas treatment systems ensure that practically all pollutants are captured within the power plant’s incineration process and only water vapor and CO2 are released from the stack. Additionally, the process of converting industrial waste into energy can be expensive, and not all locations have access to the necessary infrastructure. With increasing waste treatment and disposal costs, as well as tightening regulation, industrial WtE is actually proving the most cost-efficient way of handling industrial waste streams.

Overall, industrial waste to energy is a promising form of energy production that has the potential to reduce the amount of waste sent to landfills, reduce the amount of carbon dioxide and other pollutants released into the atmosphere, and reduce the need for traditional sources of energy. While it does come with some drawbacks, the potential benefits make it a viable option for businesses and organizations looking to reduce their carbon footprints.

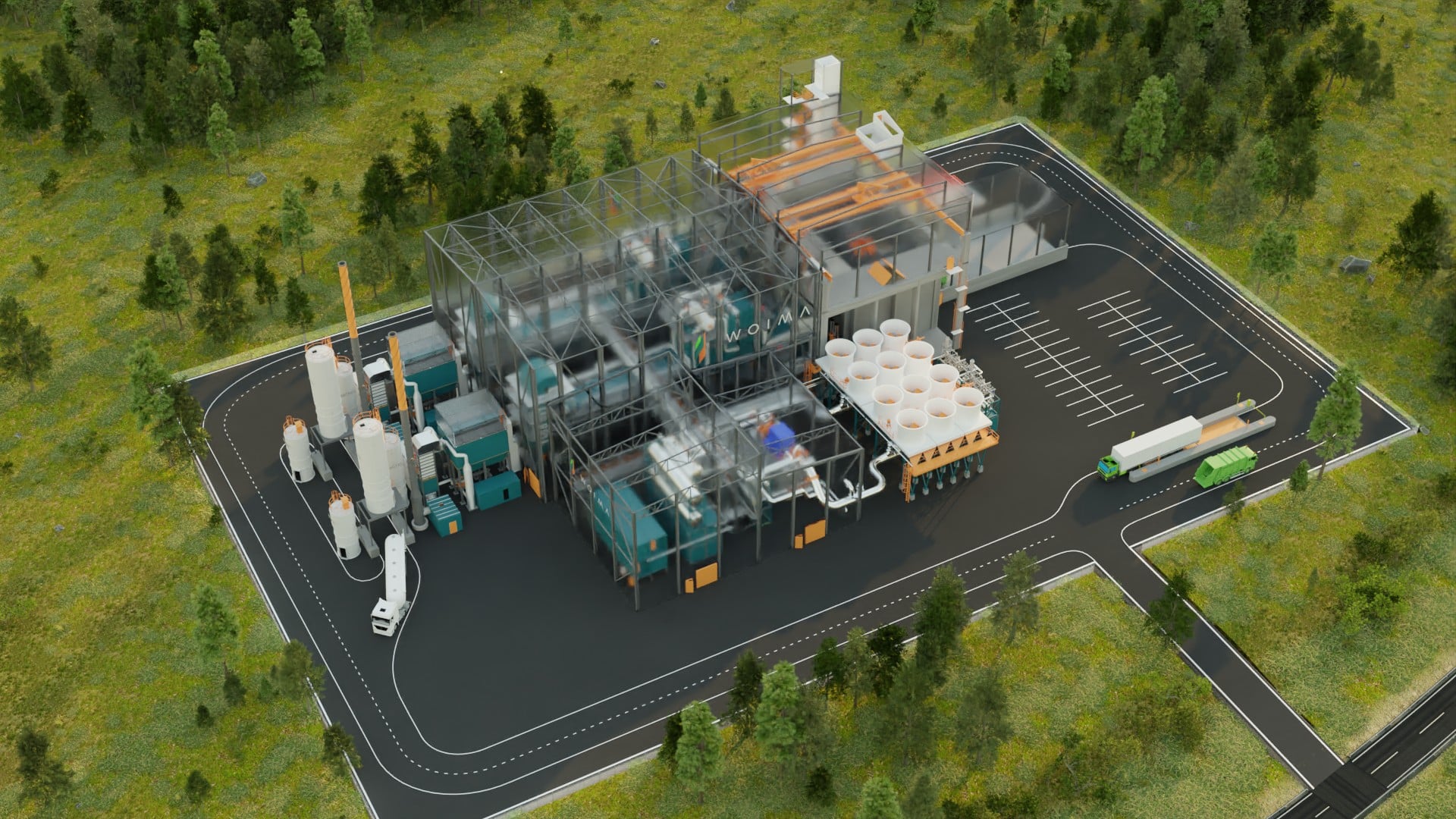

Our offering to treating industrial and other non-hazardous and semi-hazardous wastes, the wasteWOIMA® WtE plant, is a robust solution for combusting different waste streams to energy. The combustion temperature of well over 1000oC and retention time at 850oC for over two seconds ensure the safe and full combustion of the waste streams. A single boiler island (WOIMAline) wasteWOIMA® plant uses roughly 40,000 to 50,000 tons of waste fuel per annum. Several WOIMAlines can be integrated to create a larger power plant. The state-of-the-art flue gas treatment renders the combustions gases inert and safe enabling the construction of the plant also in populated areas.

Read more about the industrial waste treatment processes at Fortum, Finland

WOIMA ECOSYSTEM USE CASE FOR 250 TPD of MSW

Read more about us at www.woimacorporation.com

WOIMA Corporation is a Finnish supplier of best-in-class waste-to-value products, projects and services worldwide. We have developed solutions that enable us, and the customer, to transform and recycle virtually any waste stream into raw materials and energy. At WOIMA we combine Finnish engineering know-how in waste management with power generation design expertise. These solutions are used in Finland every day. They support the circular economy ideology and ensure that less than 1% of Finland’s waste ends up in landfills.

Our mission is to improve quality of life both locally and globally, as well as empower people to utilize waste as a commodity. Our decades of international project management experience ensure an on-time, in-budget and high-quality WOIMA solution delivery across the globe.