Why a Standardized Small-Scale Solution is an Ideal Fit? – WOIMA Blog 3/2023

The EPCM delivery model is an effective way of delivering waste-to-energy (WtE) power plants. By utilizing a combination of engineering, procurement, and construction management services, the EPCM delivery model offers an efficient and cost-effective solution to the WtE sector. It enables a quicker implementation, improved quality control, and greater flexibility within the project. Standardized small-scale solutions offer a flexible platform for project implementation. With the EPCM delivery model, developers can focus on the essential aspects of their project while benefitting from the expertise of the EPCM team.

The Engineering, Procurement, Construction and Management (EPCM) delivery model is a popular way of delivering energy and infrastructure projects of any size, such as a waste-to-energy (WtE) power plants. This delivery model is used to reduce the overall cost of the project and to ensure that the project is completed on time and on budget.

The EPCM delivery model involves the project owner engaging an EPCM contractor to provide a comprehensive package that includes all engineering, procurement, and construction management services. The EPCM contractor is responsible for the overall project delivery, i.e. designing, procuring, and managing the construction activities from concept to commissioning. Typically, the actual construction work and specific disciplines are delegated to specialist subcontractors. This allows the contractor to focus on the big picture and ensures that all components of the project are managed in a cohesive manner.

The EPCM delivery model is particularly well-suited to energy and infrastructure projects, such as WtE power plants. The contractor is responsible for procuring the necessary materials, equipment, and services for the project and for managing the construction process. The contractor also manages the project’s schedule, cost, and quality, as well as any changes to the project scope. The EPCM delivery model ensures that the project owner has maximum control over the project and that all parties involved are accountable for their actions. This delivery model also reduces the project risk by ensuring that the contractor is responsible for the successful completion of the project.

The EPCM model is quickly becoming one of the most important aspects of the global construction industry. As projects become increasingly complex, the need for efficient, cost-effective solutions is higher than ever. Standardized small-scale solutions are an ideal fit for EPCM as they provide an efficient and cost-effective way to manage projects. Standardized solutions are designed to be modular, allowing them to be quickly and easily adapted to meet the specific needs of each project. This makes them an ideal fit for EPCM as they can be quickly implemented and modified as needed.

Additionally, these solutions are often designed to be compatible with a variety of software and hardware platforms, meaning they can be quickly integrated into existing systems. Another benefit of standardized solutions is that they are often able to provide a high degree of scalability. This means that they can be easily scaled up or down to meet the needs of any project, making them an ideal fit for EPCM projects. This scalability also makes them more cost-effective, as they can be used to manage projects of any size.

EPCM also mitigates project risks efficiently, as it relies on effective risk management to ensure projects are completed on time and within budget. The EPCM process begins with a detailed risk assessment that identifies the potential risks associated with the project. This assessment is used to develop a risk mitigation plan that outlines strategies for reducing, or eliminating, the identified risks. Standardized solutions benefit from all previous project work and ensure thorough understanding of related risks and help draft efficient risk mitigation plans.

During the construction stage of the project, the risk mitigation plan is used to monitor and manage the risks associated with the project. The EPCM process also includes the development of a detailed project management plan. This plan outlines the project goals, timelines, budgets, and resources required to complete the project. Risk mitigation strategies are integrated into the project management plan to ensure that risks are managed throughout the project.

Overall, the EPCM delivery model is an effective way of delivering energy and infrastructure projects, such as WtE power plants. This delivery model ensures that the project is completed on time and on budget, while providing maximum control and accountability to the project owner.

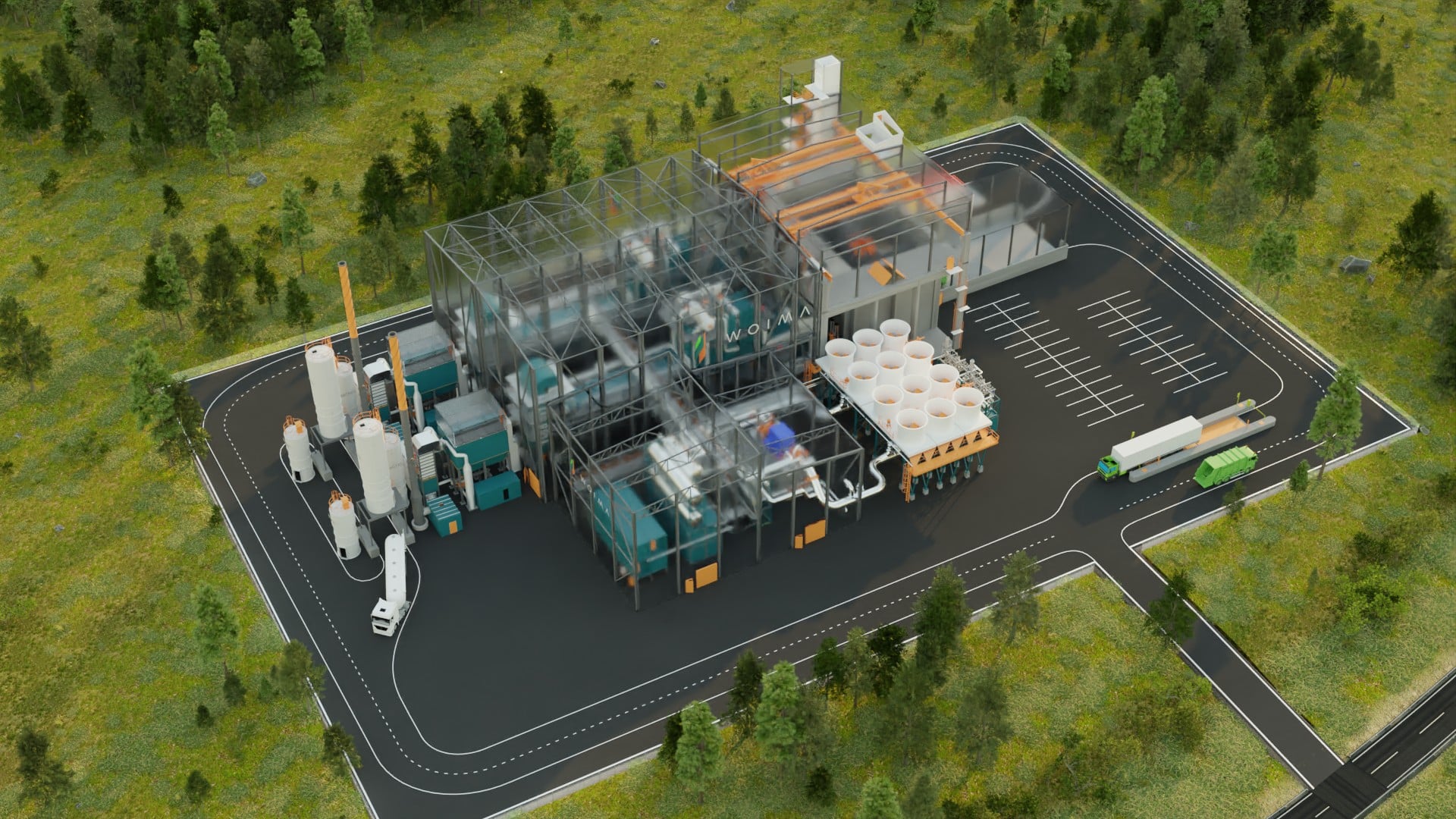

Our offering to the small-to-medium-scale WtE market, the pre-engineered, prefabricated, and modular wasteWOIMA® WtE plant, is a robust solution for combusting different waste streams to energy. A single boiler island (WOIMAline) wasteWOIMA® plant uses roughly 40,000 to 50,000 tons of waste fuel per annum. Several WOIMAlines can be integrated to create a larger power plant. The state-of-the-art flue gas treatment renders the combustions gases inert and safe enabling the construction of the plant also in populated areas.

Read more about the EPCM delivery model by a leading service provider AFRY

Read more about our waste-to-energy solutions below

Decentralized Waste-to-Energy Solution

Read more about us at www.woimacorporation.com

WOIMA Corporation is a Finnish supplier of best-in-class waste-to-value products, projects and services worldwide. We have developed solutions that enable us, and the customer, to transform and recycle virtually any waste stream into raw materials and energy. At WOIMA we combine Finnish engineering know-how in waste management with power generation design expertise. These solutions are used in Finland every day. They support the circular economy ideology and ensure that less than 1% of Finland’s waste ends up in landfills.

Our mission is to improve quality of life both locally and globally, as well as empower people to utilize waste as a commodity. Our decades of international project management experience ensure an on-time, in-budget and high-quality WOIMA solution delivery across the globe.